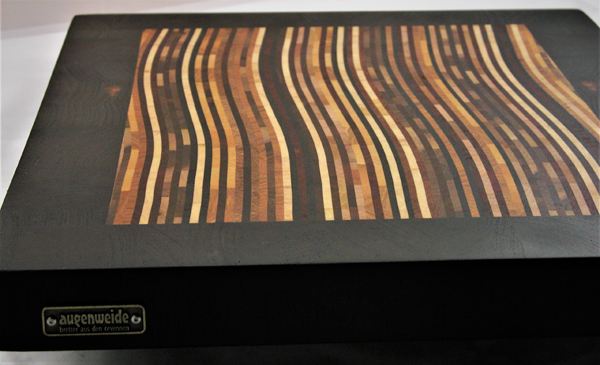

Handcrafted and unique

End grain cutting boards made in southern France

The Cutting Board For A Lifetime

You have come to the right place if you are interested in individual and professionally manufactured end grain cutting boards or breakfast boards.

End grain cutting boards not only fascinate with their beautiful surface and

individual patterns but are particularly suitable for daily use in sophisticated

kitchens and households.

Compared to a board surface with parallel wood strands, The end grain wood

surface can resist cutting pressure by a multitude. This outstandingly cut-

resistant surface of our end grain boards is achieved by an upright orientation

of the individual end grain elements each board consists of. The result is a

surface in which all wood fibers stand upright like a brush and are not severed

during cutting as usually the case with common wood boards using parallel

wood fiber orientation.

This surface is not only extremely cut-resistant, but also protects the blades.

Chopping blocks are often made from end grain wood for the same reason.

The high pressure developing during the chopping process is evenly

distributed avoiding deep penetration into the wood and significantly reducing

surface damage compared to common cutting boards.

Due to the inherent capillary effect of the fibers across the entire surface, all

moisture is absorbed and released quickly, improving a natural antibacterial

effect of wood.

All end grain cutting boards can be sanded and finished to return to its original

smooth surface.